Black steel

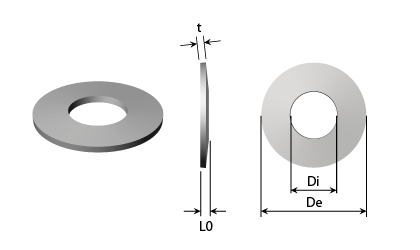

Disc springs are a good choice in structures where high strength is required but space is limited. By combining several disc springs in layers it is possible to achieve varying force and travel.

We have most dimensions in stock, ready for dispatch. Please note we do not have prices for the largest disc springs. Please contact us for further information.

- 600-320-30In stock: 18,544Material Oiled spring steelDe - External diameter (mm) 6.00Di - Internal diameter (mm) 3.20t - Thickness (mm) 0.30L0 - Unloaded length (mm) 0.45L - Height in load F (mm) 0.34F - Force (N) 119.00s - Max travel (mm) 0.11

- 00800200In stock: 13,635Material Oiled spring steelDe - External diameter (mm) 8.00Di - Internal diameter (mm) 3.20t - Thickness (mm) 0.20L0 - Unloaded length (mm) 0.40L - Height in load F (mm) 0.25F - Force (N) 26.00s - Max travel (mm) 0.15

- 800-320-20In stock: 19,856Material Oiled spring steelDe - External diameter (mm) 8.00Di - Internal diameter (mm) 3.20t - Thickness (mm) 0.20L0 - Unloaded length (mm) 0.40L - Height in load F (mm) 0.25F - Force (N) 26.00s - Max travel (mm) 0.15

- 800-320-30In stock: 19,937Material Oiled spring steelDe - External diameter (mm) 8.00Di - Internal diameter (mm) 3.20t - Thickness (mm) 0.30L0 - Unloaded length (mm) 0.55L - Height in load F (mm) 0.36F - Force (N) 104.30s - Max travel (mm) 0.19

- 00800300In stock: 332Material Oiled spring steelDe - External diameter (mm) 8.00Di - Internal diameter (mm) 3.20t - Thickness (mm) 0.30L0 - Unloaded length (mm) 0.55L - Height in load F (mm) 0.36F - Force (N) 105.00s - Max travel (mm) 0.19

- 800-320-40In stock: 19,428Material Oiled spring steelDe - External diameter (mm) 8.00Di - Internal diameter (mm) 3.20t - Thickness (mm) 0.40L0 - Unloaded length (mm) 0.60L - Height in load F (mm) 0.45F - Force (N) 185.50s - Max travel (mm) 0.15

- 00800400In stock: 371Material Oiled spring steelDe - External diameter (mm) 8.00Di - Internal diameter (mm) 3.20t - Thickness (mm) 0.40L0 - Unloaded length (mm) 0.60L - Height in load F (mm) 0.45F - Force (N) 186.00s - Max travel (mm) 0.15

- 800-320-50In stock: 19,735Material Oiled spring steelDe - External diameter (mm) 8.00Di - Internal diameter (mm) 3.20t - Thickness (mm) 0.50L0 - Unloaded length (mm) 0.70L - Height in load F (mm) 0.55F - Force (N) 357.40s - Max travel (mm) 0.15

- 800-420-20In stock: 18,512Material Oiled spring steelDe - External diameter (mm) 8.00Di - Internal diameter (mm) 4.20t - Thickness (mm) 0.20L0 - Unloaded length (mm) 0.45L - Height in load F (mm) 0.26F - Force (N) 39.20s - Max travel (mm) 0.19

- 800-420-30In stock: 24,343Material Oiled spring steelDe - External diameter (mm) 8.00Di - Internal diameter (mm) 4.20t - Thickness (mm) 0.30L0 - Unloaded length (mm) 0.55L - Height in load F (mm) 0.36F - Force (N) 117.90s - Max travel (mm) 0.19

Thicknesses of finished disc springs may measure less than the specified thickness as the specified thickness is before machining.

Stainless steel 304: W. Nr. 1.4301

Stainless steel 316: W. No. 1.4401

Thicknesses of finished disc springs may measure less than the specified thickness as the specified thickness is before machining.

All our disc springs are magnetic - including those in AISI 316. This is due to the way they are produced. If non-magnetic disc springs are desired, please contact us at: [email protected]

Springs are dimensioned according to DIN 2093. The dimensions in the catalogue are unmachined measurements. Therefor measurements may differ from those in the catalogue tables. This applies to diameters and thickness.

The force is calculated theoretically. It is intended as a guide, with scope for large tolerances.

The springs 50 CrV4 & Stainless 304 & stainless 316 are dimensioned according to DIN 16983, which gives the following tolerances.

The force is calculated theoretically. It is intended as a guide, with scope for large tolerances.

If you want a PDF datasheet or a 3D CAD drawing of the spring in .step, .iges or .sat format, these can be downloaded for free by clicking on the 3D CAD symbol next to the item number in the table.

The service life of a spring is generally very difficult to define. A large number of parameters come into play, and it is therefore impossible to define a service life.

Parameters with a significant influence on service life include: Installation, installation method, number of movements, vibrations, shocks, torsion, length of travel, non-axial travel, temperature, wear against other surfaces, environment of use, any cleaning agents, lateral impacts, etc.

Applying the maximum load to the spring or exceeding it will shorten its service life and may cause it to become permanently distorted.

Internet Explorer Incompatibility

This website unfortunately does not work well with Internet Explorer. We recommend using one of the following free browsers: