Mechanical "Gas Spring"

Order Monday-Thursday before 15:30 and Friday before 14:45 and we’ll dispatch your order the same day with expected delivery within 2-4 days. This applies to all stocked Mechanical "Gas Springs"

See quantity discounts and prices by clicking on the shopping cart next to the required product.

Use the range sliders below for quick and easy navigation.

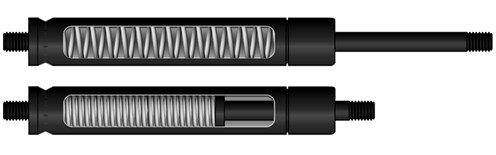

A mechanical “gas spring” is similar to a conventional compression gas spring. From the outside, you cannot tell the difference, but inside the gas and gaskets have been replaced by an ordinary wire compression spring.

Thereby, a mechanical “gas spring” can be used in dirty environments, can withstand greater loads, and can tolerate twisting and impact effects in the longitudinal direction to a greater extent. A mechanical “gas spring” must not act as a mechanical stop and the cylinder must be protected against impacts and shocks, as dents in the cylinder will prevent the free movement of the piston inside.

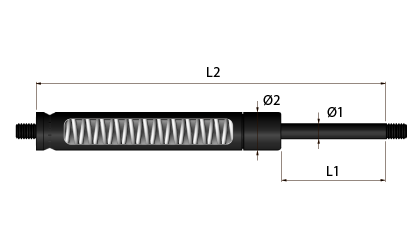

Our range of mechanical “gas springs” come with threads at both ends, which provides great flexibility in terms of ascent. The thread fits our range of end fittings that can also be used on our regular gas springs. The size of the thread depends on the piston rod.

- LMS1505102In stock: 62Material Black painted steelØ1 - Piston Rod diameter (mm) 6.00Ø2 - Tube diameter (mm) 15.00L1 - Stroke (mm) (+/- 2 mm) 51.00L2 - Unloaded length between thread (mm) (+/- 3 mm) 156.00Fn - Maximum load at Ln (N) 27.00G - Thread (M) 6.00

- LMS1510205In stock: 60Material Black painted steelØ1 - Piston Rod diameter (mm) 6.00Ø2 - Tube diameter (mm) 15.00L1 - Stroke (mm) (+/- 2 mm) 102.00L2 - Unloaded length between thread (mm) (+/- 3 mm) 309.00Fn - Maximum load at Ln (N) 67.00G - Thread (M) 6.00

- LMS1515205In stock: 5Material Black painted steelØ1 - Piston Rod diameter (mm) 6.00Ø2 - Tube diameter (mm) 15.00L1 - Stroke (mm) (+/- 2 mm) 152.00L2 - Unloaded length between thread (mm) (+/- 3 mm) 461.00Fn - Maximum load at Ln (N) 67.00G - Thread (M) 6.00

- LMS1520306In stock: 94Material Black painted steelØ1 - Piston Rod diameter (mm) 6.00Ø2 - Tube diameter (mm) 15.00L1 - Stroke (mm) (+/- 2 mm) 203.00L2 - Unloaded length between thread (mm) (+/- 3 mm) 613.00Fn - Maximum load at Ln (N) 80.00G - Thread (M) 6.00

- LMS1525407In stock: 11Material Black painted steelØ1 - Piston Rod diameter (mm) 6.00Ø2 - Tube diameter (mm) 15.00L1 - Stroke (mm) (+/- 2 mm) 254.00L2 - Unloaded length between thread (mm) (+/- 3 mm) 766.00Fn - Maximum load at Ln (N) 94.00G - Thread (M) 6.00

- LMS1530507In stock: 67Material Black painted steelØ1 - Piston Rod diameter (mm) 6.00Ø2 - Tube diameter (mm) 15.00L1 - Stroke (mm) (+/- 2 mm) 305.00L2 - Unloaded length between thread (mm) (+/- 3 mm) 918.00Fn - Maximum load at Ln (N) 95.00G - Thread (M) 6.00

- LMS1805103In stock: 15Material Black painted steelØ1 - Piston Rod diameter (mm) 8.00Ø2 - Tube diameter (mm) 18.00L1 - Stroke (mm) (+/- 2 mm) 51.00L2 - Unloaded length between thread (mm) (+/- 3 mm) 166.00Fn - Maximum load at Ln (N) 40.00G - Thread (M) 6.00

- LMS1810207In stock: 40Material Black painted steelØ1 - Piston Rod diameter (mm) 8.00Ø2 - Tube diameter (mm) 18.00L1 - Stroke (mm) (+/- 2 mm) 102.00L2 - Unloaded length between thread (mm) (+/- 3 mm) 319.00Fn - Maximum load at Ln (N) 93.00G - Thread (M) 6.00

- LMS1815209In stock: 38Material Black painted steelØ1 - Piston Rod diameter (mm) 8.00Ø2 - Tube diameter (mm) 18.00L1 - Stroke (mm) (+/- 2 mm) 152.00L2 - Unloaded length between thread (mm) (+/- 3 mm) 471.00Fn - Maximum load at Ln (N) 120.00G - Thread (M) 6.00

- LMS1820309In stock: 40Material Black painted steelØ1 - Piston Rod diameter (mm) 8.00Ø2 - Tube diameter (mm) 18.00L1 - Stroke (mm) (+/- 2 mm) 203.00L2 - Unloaded length between thread (mm) (+/- 3 mm) 623.00Fn - Maximum load at Ln (N) 120.00G - Thread (M) 6.00

Piston Rod: Steel, which is nitride-treated - resistant to corrosion.

Cylinder: Steel, painted black

Wire spring: Spring steel, Chrome Silicon Alloy

Working temperature between -40 ºC and +200 ºC

Max force (Fn): +/- 15 %

Stroke (L1): +/- 3 mm

Total length between thread (L2): +/- 6 mm

If you want a PDF datasheet or a 3D CAD drawing of the spring in .step, .iges or .sat format, these can be downloaded for free by clicking on the 3D CAD symbol next to the item number in the table.

The wire spring gives Mechanical "Gas Springs" a regular linear force curve - in contrast to the flatter force curve of conventional gas springs.

As Mechanical "Gas Springs" has no oil in the cylinder, it is not dampened in the last portion of its full extension.

Mechanical "Gas Springs" is used instead of gas springs in structures subject to impacts and vibrations. Mechanical "Gas Springs" may be used to great advantage in dirty and dusty environments, where a gas spring would suffer leakage due to its surroundings.

Mechanical "Gas Springs" is a good choice in structures where its function is used only rarely - such as emergency exits. Mechanical "Gas Springs" can cope with being subjected to loads over a prolonged period without being moved.

Mechanical "Gas Springs" must not be used as a stop, but should be incorporated so that it is controlled and limited by the movement of the structure.

Our large range of End Fittings can also be used on Mechanical "Gas Springs" - and provide great flexibility in installation.

The service life of a spring is generally very difficult to define. A large number of parameters come into play, and it is therefore impossible to define a service life.

Parameters with a significant influence on service life include: Installation, installation method, number of movements, vibrations, shocks, torsion, length of travel, non-axial travel, temperature, wear against other surfaces, environment of use, any cleaning agents, lateral impacts, etc.

Applying the maximum load to the spring or exceeding it will shorten its service life and may cause it to become permanently distorted.