How do you design a compression spring?

General considerations regarding the design and calculation for a compression spring.

We design and calculate compression springs every day, so we often come across the same questions. Here we will go through the construction of a compression spring, and explain what parameters need to be defined.

Compression spring material

First define the material that matches your purpose and design. For correct calculation of your compression spring, the material should serve as the starting point.

Examples of the most commonly used spring materials.

Compression spring wire diameter

The force of a compression spring is defined by a combination of the thickness of the wire, its diameter, the number of coils and its free length. The thinner the wire used, the less force and stability there is in the spring. Thin wire, big diameter and many coils result in an unstable spring with a flat force curve. Thick wire, small diameter and few coils result in a steeply increasing force curve and short travel.

If you increase the diameter of a wire it has a big impact on the force, since the area is increased markedly.

Compression spring diameter

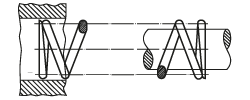

If a compression spring has to operate over a mandrel, the inside diameter is the starting point. If the working hole for the compression spring is not variable, the outside diameter is the starting point. The diameter of a compression spring will be increased when the spring is compressed. This increase is commensurate with the pitch of the compression spring. The greater the pitch, the greater the increase in diameter. It is therefore important to know the tolerance of the outside diameter and to take account of this in the design of the spring and its construction.

If the diameter of the spring is increased, the force of the spring is reduced.

Compression spring length

If possible, in your assembly, use a spring with as little travel as possible, in order to prolong the service life of the spring.

Short spring, here maximum travel is used = short service life

Long spring, here minimum travel is used = long service life

If you increase the length of the spring, maximum force is retained, but the spring constant is reduced.

Compression spring coils

Few coils = short travel

Many coils = long travel

A big gap between coils = steep coil = steep force curve. Long travel not given, as tension in the wire reaches maximum more quickly due to few coils.

Small gaps between coils = short travel before coils touch one another. Flat force curve.

If the number of coils is increased, the force of the spring is reduced.

Compression spring end

The end of a compression spring may be one of the following.

Compression spring direction of wind